EmJ - Electronic Modulating Ejector

Transcritical CO2 systems can now be optimised

for operation in warmer climates...

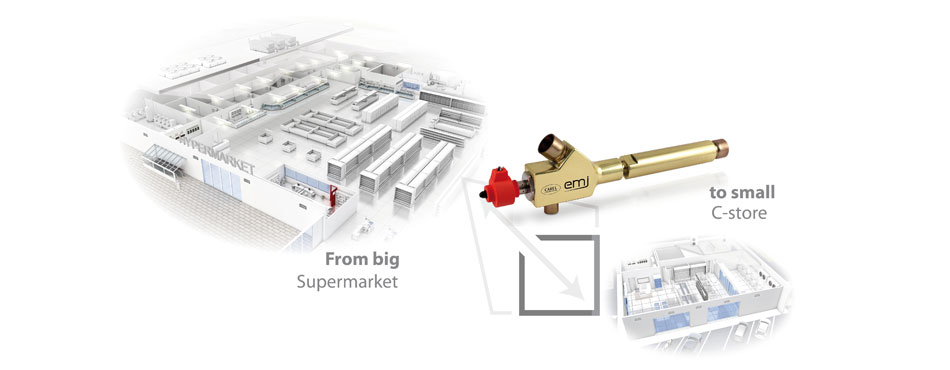

...from small convenience stores to large supermarkets

Electronic modulating ejectors represent a cutting-edge solution that increase the energy efficiency of transcritical CO2 systems in warmer climates, sustainably extending the possibility to use CO2 as a natural refrigerant

An ejector is a device that exploits the energy of a high-pressure fluid flowing through a nozzle to carry and compress another fluid at much lower pressure.

The fundamental feature of the solution is the continuous modulation ensured by ejectors, which via dedicated control algorithms allow the system to continuously adapt to the typical variations in refrigeration system operating conditions.

Continuous modulation

Continuous modulation represents the forefront of CAREL’s solutions, from electronic expansion valves to control systems for BLDC compressors and now modulating ejectors. Through such precise continuous modulation, CAREL can ensure the highest system efficiency, managing different operating conditions and adapting to different system requirements in the most optimum way, especially at part loads.

Continuous modulation simplifies what is actually intrinsically complex technology. This is why CAREL has applied this concept to its range of ejectors, a unique feature allowing the use of just one self-adapting device to guarantee optimum energy efficiency.

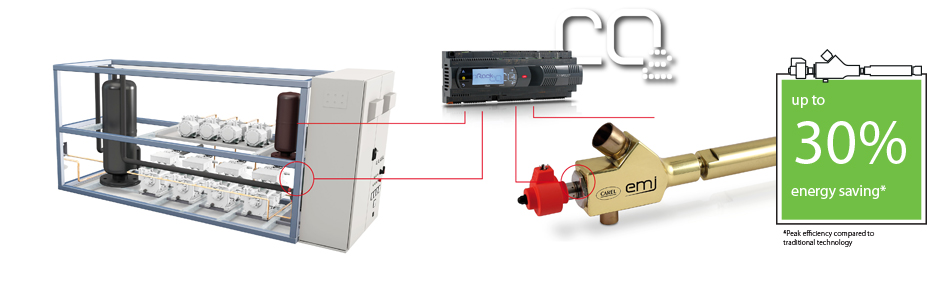

Increased efficiency

EmJ and the specifically designed rack where it is installed reduces system complexity, as it can continuously and instantly adapt to specific operating conditions, ensuring an increase in system performance of up to 25% in design operating conditions and up to 12% overall throughout the year.

All this is based on:

- direct expansion work recovery due to the Venturi effect;

- higher evaporation temperature in MT cabinets;

- higher suction pressure in all MT compressors.

EmJ completely overcomes the concept of “CO2 equator” created several years ago, boosting efficiency all over the world.

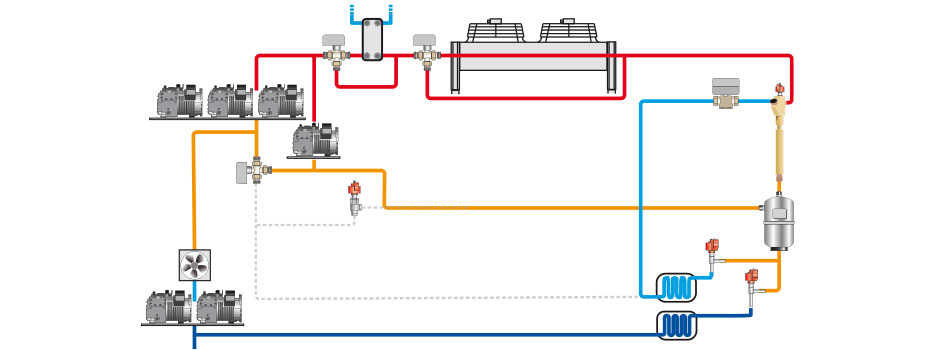

Simplified systems

Modulating ejector optimizes installation costs and complexity, as it can continuously and instantly adapt to specific operating conditions and continuous modulation directly increase energy efficiency of CO2 transcritical systems in all working conditions.

EmJ modulating ejectors can be fully disassembled and inspected, and the body is installed separately, allowing the actuator to be removed independently; this makes installation and maintenance extremely simple.

The use of modulating ejectors with the CAREL pRack pR300T compressor rack controller allows integrated and synchronised management of all the rack’s components. The advanced algorithms that ensure energy efficiency and precise control also further simplify the system, allowing for example the reuse of compressors that are not traditionally used in certain operating modes, thus reducing the number of compressors needed (medium temperature compressors that can operate with a pressure differential that is typical of parallel compressors).

The overall result is a reduction in the number of compressors needed for the same cooling capacity as a system without CAREL modulating ejectors In subcritical conditions, EmJ ejectors tend to work as a modulating high pressure valve, thus eliminating the need to install additional valves, which would be redundant, even in transcritical conditions.

Scalability

The modulating vapour ejector range includes a number of different ejector sizes, all of which have the ability to vary capacity across a given range. The CAREL EmJ range covers different cooling capacities, from a few kW to over one hundred kW, thus providing maximum flexibility when designing racks for various applications. From small stores to large supermarkets, the energy efficiency of transcritical CO2 refrigeration systems can now also be sustainable in warmer climates.