Refrigerant circuit components

"Vapor compression refrigeration cycle" is the name give to describe the operation of the closed circuits used in refrigeration applications.

This exploits the evaporation of a refrigerant inside the circuit, specifically in a heat exchanger called the evaporator, which absorbs energy from the surrounding air; this is then delivered to the food storage compartment by natural or fan-forced convection (also see "MAKING IT COLD" and "PRESSURE & TEMPERATURE").

Once having evaporated, the refrigerant can no longer absorb considerable amounts of energy, and consequently it needs to be returned to the liquid state by condensation.

The problem thus arises of having an environment that's "cold" enough to absorb energy from the refrigerant, which naturally cannot be the same storage compartment that's just been cooled.

By exploiting the correlation between pressure and temperature for change of state whereby higher pressures correspond to higher temperatures, a compressor is used to compress the refrigerant to a pressure that's higher than the evaporator (up to 10 times!) so that the condensation process can take place at a temperature that's compatible with a readily available "cold" source, typically the outside air.

Condensation thus occurs at a high temperature (usually 35-55°C) inside a heat exchanger where the two substances are outside air and refrigerant. The latter condenses and returns to the liquid state, while the outside air will be heated.

The liquid refrigerant is still at high pressure when it leaves the condenser. An expansion device is thus needed to expand the liquid refrigerant and reduce its pressure to the value at which evaporation occurs; the refrigerant has now returned to its initial state (liquid at low pressure and temperature) and can once again absorb energy from the air in the food storage compartment.

The main components of a refrigerant circuit are therefore:

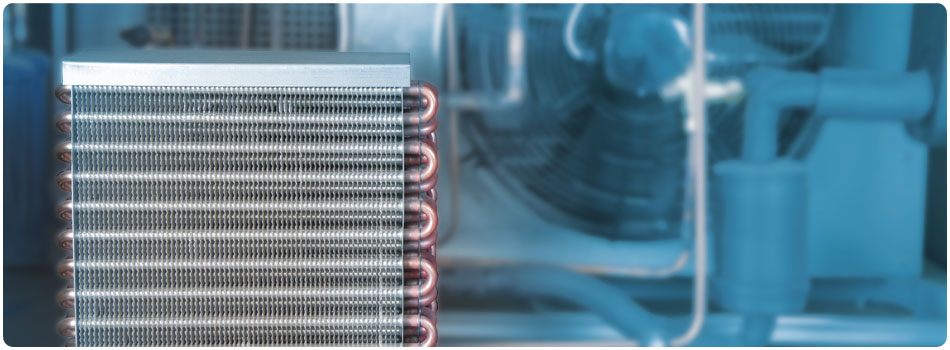

Evaporator: this is a heat exchanger similar to a radiator when used with air (finned coil) or more compact when used with water (plate heat exchanger, tube bundle); it exchanges energy by conduction between the refrigerant that evaporates, changing state from liquid to gas, and the surrounding air (or water) that's cooled as a result. Evaporation takes place at virtually constant pressure and temperature, except for a slight pressure drop. The refrigerant leaving the evaporator is a superheated gas whose temperature is slightly higher than evaporation temperature.

Compressor: this is a device providing volumetric compression, i.e. a progressive reduction in volume, using rotating or reciprocating systems. The compressor has the function of circulating refrigerant inside the circuit, specifically drawing it in as a gas from the evaporator and then compressing it and delivering it at higher pressure to the condenser. The mechanical work performed by the compressor generates a significant increase in the temperature of the gas (at times above 100°C) as well as power consumption. Compressor power consumption depends on the difference between the two operating pressures. The refrigerant entering the compressor must be in the gaseous state, as liquids are notoriously incompressible. The compressor starts working when the unit needs to provide cooling, and is usually activated via temperature control systems.

Condenser: this is a heat exchanger that's similar to an evaporator yet slightly larger, and may also be a finned coil, plate heat exchanger or tube bundle. It exchanges energy between the outside air (or water) blown by fans and the refrigerant in the form of hot gas discharged by the compressor. The refrigerant is cooled and then condenses at a virtually constant temperature and pressure, meaning it undergoes slight subcooling. At the condenser outlet the refrigerant will be in the liquid state at high pressure and with a temperature slightly lower than the condensing temperature.

Expansion device: this consists of a calibrated opening, a thin capillary tube or a mechanical or motor-driven regulating valve with microprocessor control. The choking produced by the expansion device lowers the pressure of the liquid refrigerant leaving the condenser without exchanging energy. This exploits the Bernoulli principle whereby the speed of a fluid through a restriction increases significantly, causing a drop in pressure and a corresponding drop in temperature. In this way, the liquid refrigerant returns to low pressure and low temperature and is ready to evaporate again, repeating the cycle described above.

The expansion device also has the function of controlling refrigerant flow through the circuit. An excessive quantity risks damaging the compressor as it won't completely evaporate in the evaporator, remaining partly in liquid state. An insufficient quantity sensitively reduces unit efficiency, as the evaporator is not fully exploited.