Solutions for wood processing

The CAREL Group offers a wide range of solutions for controlling the environmental conditions in industrial processes. Humidification, heat recovery and integrated control of high-efficiency components for ventilation systems make up the core of CAREL’s know-how applied to wood processing.

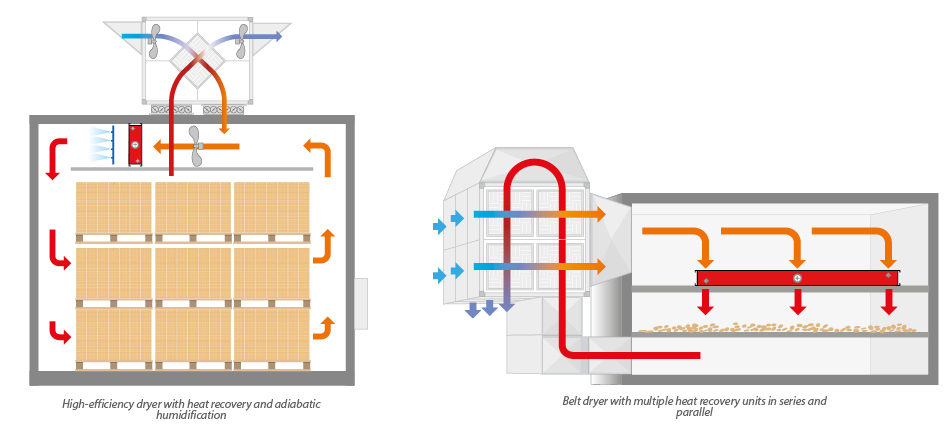

Drying processes require high-temperature, humidity-controlled air for extended periods of time. Highly-efficient components such as heat recovery units and heat pumps reduce energy consumption and CO2 emissions.

Heat recovery and lower drying costs

A traditional dryer heats air to high temperatures to help moisture evaporate from the wood. The humid released by the wood is then expelled and replaced with dry outside air. This process is energy-intensive, however it can be made more efficient using heat recovery units, modulating fans and thermally-insulated dampers, significantly reducing energy consumption.

Precise humidity control with the addition of steam or adiabatic atomisation further ensures faster drying and higher-quality wood..

Recuperator and Klingenburg, both part of the CAREL Group, offer a wide range of technical solutions for heat recovery in industrial processes.

Moreover, Enginia dampers ensure further energy savings by limiting heat losses from the stack.

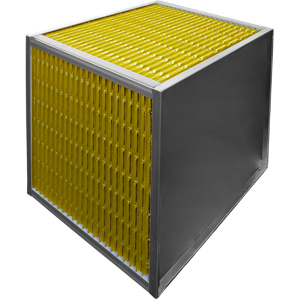

Cross-flow heat exchanger

Cross-flow heat exchanger

Recovers up to 70% of the heat from the hot and humid air leaving the dryer. Withstands high temperatures, up to 850°C, and resists corrosion from the tannins released by the wood. The choice of a wide fin pitch, GOLD coating and aluminium frame guarantees a long working life without compromising on performance.

Thermal break dampers

Thermal break dampers

Thermal break dampers with class 4 tightness guarantee the highest thermal insulation by reducing heat loss from the stack and improving control of the incoming air flow. These are especially useful for extended drying cycles.

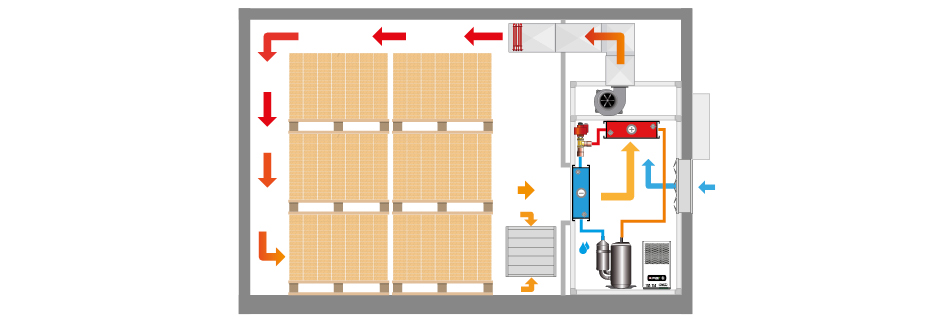

Condensation drying with heat pumps

Unlike traditional dryers, heated by boilers supplied with processing waste or by electric heaters, heat pumps can bring significant energy savings: with electric heating, 1 kW of electricity produces 860 kcal/h, while a heat pump can produce from 2000 to 3000 kcal/h per kW. In addition, the processing waste, instead of being used as fuel, can be converted into value-added products such as plywood and composite materials.

The heat pump uses a cooling coil to remove heat and humidity from the air, condensing the water vapour and expelling it. The recovered heat is then transferred to the heating coil, which generates a flow of hot, dry air, ideal for drying. The air is recirculated and high air change volumes are not needed, as in traditional dryers.

Heat pump technologies

High-efficiency solution comprising BLDC compressors, DC inverters,

High-efficiency solution comprising BLDC compressors, DC inverters,

electronic expansion valves and built-in sensors, compatible with natural refrigerants and A3

ready. The offering is completed by a range of programmable controls and

customisable proprietary software, for the development of high-added-value solutions.

Quality guaranteed by the right level of relative humidity

Relative humidity is a fundamental parameter in ensuring the stability of wood. Wood is a living material that exchanges moisture with the environment. Controlling air humidity during woodworking solves problems such as cracking, warping, assembly problems, gluing and painting defects.

CAREL offers a wide range of humidifiers and sensors for complete control of air relative humidity in places where wood is stored and processed.

heaterSteam

heaterSteam

heaterSteam is CAREL’s reliable and precise electric heater humidifier that works with any type of feedwater.

The heaterSteam thermal shock feature removes mineral deposits from the heaters, minimising the need for maintenance.

heaterSteam is the ideal choice for small and medium-sized spaces and for retrofitting existing systems, as the steam produced can be absorbed in a small area.

humiFog

humiFog

humiFog is the high-pressure adiabatic atomiser for humidification and evaporative cooling, featuring high efficiency and low energy consumption (4 W per l/h).

Ideal for humidity control in large industrial environments, for suspended dust abatement and for reducing electrostatic phenomena.

High system flexibility, support during solution design, guaranteed correct installation and dedicated maintenance programs complete the CAREL solution for customers.