evaporative cooling: cooling the air with water

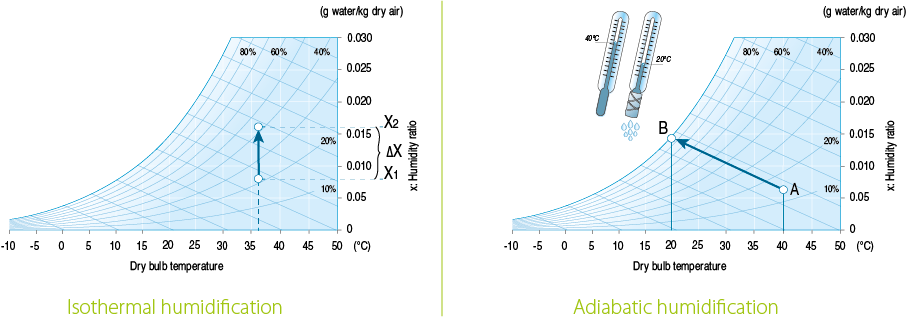

Evaporation of water requires energy: around 700 watts per litre. In the case of steam humidification, the energy needed to boil the water is supplied by an external source, usually electricity.

If however the water is introduced into the environment after having been finely atomised into microscopic droplets, it evaporates spontaneously, absorbing the required energy from the surrounding air. Consequently, the air is cooled.

It can therefore be stated that when water evaporates, the sensible heat of the air (temperature) is converted into latent heat (humidity). In literature, this process is called evaporative cooling.

100 kg of water that evaporates

absorbs around 69 kW of heat from the air,

with a power consumption of less than 1 kW.

Adiabatic humidifiers feature very low power consumption, as the only energy required goes into atomising the water. Several different technologies are available, however evaporative cooling systems are generally green, energy-saving solutions.

Adiabatic humidification can essentially be used in three situations: direct evaporative cooling, indirect evaporative cooling and for chillers and drycoolers.

Direct evaporative cooling (DEC)

DEC (Direct Evaporative Cooling) involves cooling and humidifying the fresh air taken in by an AHU. This technology is very efficient, and its maximum potential can be exploited when the outside air is hot and dry, or in applications that require both humidity control and absorption of the heat generated by equipment, such as in data centers.

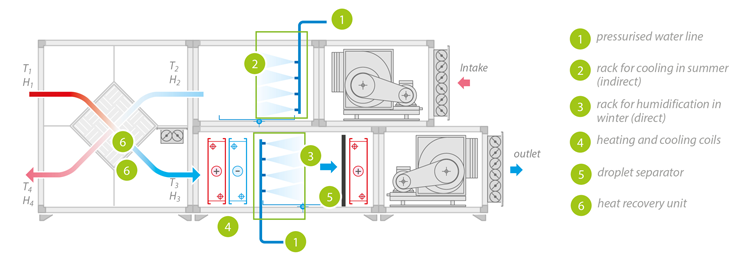

Indirect evaporative cooling (IEC)

If the outside humidity is already high, on the other hand, IEC (Indirect Evaporative Cooling) can be exploited. This technique uses an adiabatic humidifier combined with a heat exchanger, either a plate exchanger or run-around coil. The return air is humidified and cooled before being discharged, and in turn cools the fresh air intake via the heat exchanger. IEC therefore has two unique features: the fresh air stream is cooled without being humidified, which is positive as in temperate climates summers are often hot and humid, and above all the two air streams are not mixed, a fundamental requirement in applications where air purity is strictly controlled, such as in the pharmaceutical industry.

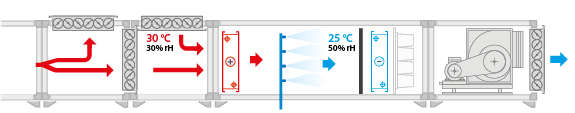

Evaporative cooling for chillers and drycoolers

Installing pressurised water atomisers near a chiller or drycooler allows the outside air to be cooled with minimum power consumption: the resulting effect is to have the system operate as if the temperature were lower. For example, even at temperatures of over 30°C, the cooling system works at an equivalent temperature of 25°C, and operates perfectly even during peak summer temperatures, when normally it would not be able to dissipate the heat due to excessive outside air temperature.

Evaporative cooling techniques can be easily integrated into existing systems, bringing the following benefits:

lower upfront investment;

lower upfront investment;

substantial energy savings: less energy needed for cooling;

substantial energy savings: less energy needed for cooling;

reduction in peak power demand and thus less dependence on electricity;

reduction in peak power demand and thus less dependence on electricity;

no chlorofluorocarbons used;

no chlorofluorocarbons used;

smaller duct dimensions and size (kW) of the cooling appliances;

smaller duct dimensions and size (kW) of the cooling appliances;

reduction in system CO2 emissions; lower running costs throughout the appliance life cycle.

reduction in system CO2 emissions; lower running costs throughout the appliance life cycle.

CAREL features a vast range of solutions, with a wide range of flow-rates, features and operating modes, for both installation in ducts and to cool/humidify directly in rooms.